Forging Capabilities

From conventional to precision forging solutions, we have the technical capacity to handle projects of varying complexities and dimensions. Our commitment to excellence ensures that each component meets the most exacting standards, providing our clients with superior metallurgical integrity and performance reliability.

Forging Presses

42 Hydraulic Forging Presses

• Tonnage Range from 300 to 8,000

9 Mechanical Forging Presses

• Tonnage Range from 600 to 4,000

3 Spin Forging Centers

• Flow Form up to 24″ in Diameter

Press Capabilities

Conventional Forging: Up to 650 Square Inches in Plan View Area (PVA)

Precision Forging: Up to 350 Square Inches in Plan View Area (PVA)

Spinner Capabilities: Up to 24″ in Diameter for Wheels, Cones, Etc.

Metallurgy Lab

APP’s state of the art metallurgy laboratory is staffed to test aluminum alloys for strength and hardness, and is Nadcap approved. We are capable of performing the following tests on aluminum alloys:

- Room Temperature Testing (Round & Flat Specimens)

- Hardness

- Electrical Conductivity

- Chemistry

- Microstructure/Intergranular Corrosion Testing

- Grain Flow Testing

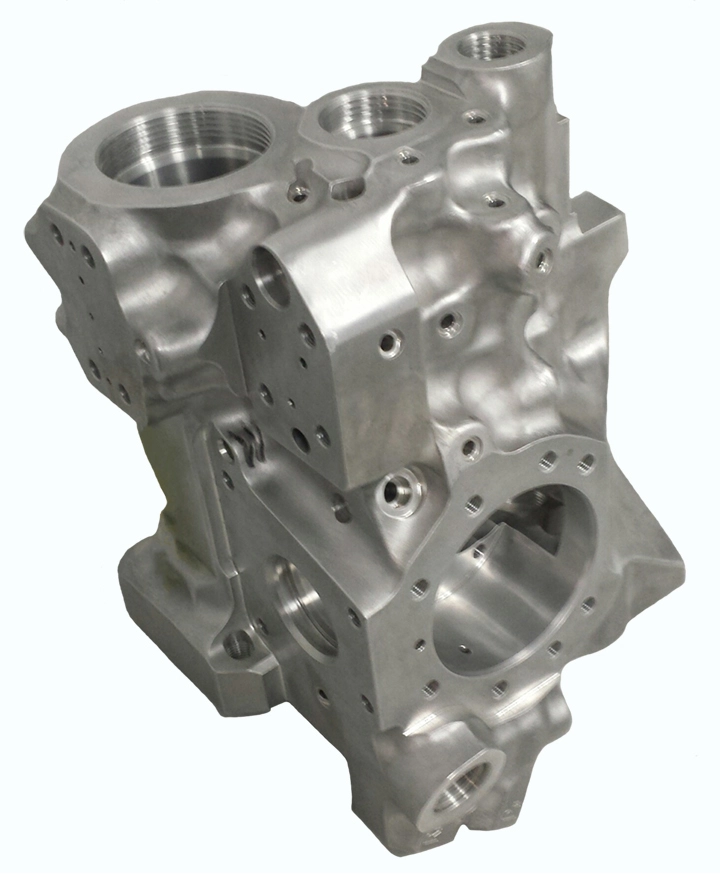

Machining & Trim Equipment

Trim Equipment

- Mechanical Trim Presses (1-50 ton; 2-50 ton)

- Water Jet Cutter 3-Axis CNC 96″ x 144″ x 12″

Machining Capabilities:

CNC Milling

Including Horizontal 4-Axis Automated Pallet Cells

An array of 3, 4, 5-Axis

- Kitamura

- Makino

- Mazak

- Mori-Seiki

- OKK

- Okuna

Spindle Speed

- 15,000 RPM

5-Axis Horizontal (Up to 28″ envelope)

4-Axis Horizontal (Up to 55″ length)

- No setup time

- Dedicated tombstones

3-Axis Vertical Mills (Up to 80″ length)

5-CNC Lathes (Up to 34″)

- Close to Tolerance Jig Boring & Jig Grinding

- Tol. to 0.0005 dimension/location

Process & Inspection

Our integrated process chain combines sophisticated thermal treatments with rigorous quality assurance systems. We offer complete heat treat options through vertical batch and horizontal continuous furnaces, backed by comprehensive inspection capabilities including DCC-CMM dimensional verification, fluorescent penetrant testing, ultrasonic evaluation, and metallurgical certification. We complete each component with professional surface finishing treatments to meet the most demanding industry specifications.

Thermal Treatment:

- Vertical Batch heat treat furnaces

- Horizontal continuous heat treat furnaces

Inspection:

- Fully Equipped & Staffed

- DCC-CMM Dimensional Inspection

- Fluorescent Penetrant Inspection

- Ultrasonic Testing (Stock & Parts)

- Certified Metallurgical Lab

Surface Finishing:

- Shot Peen

- Anodize

- Prime

Engineering & Design

APP utilizes the most advanced engineering platforms for solid modeling, tool design and metal flow simulation in the development and fabrication of forging tooling. We are capable of receiving solid model part designs in virtually any format, translating or transferring them to our platforms and designing the optimum tools for the most economical forging approaches.

Our engineering personnel are available for co-located or concurrent engineering activities with your engineers in the nascent stages of design development that can save time on project development adjustments often incident to new forging designs.

- CATIA V5-6R2021

- CATIA Enovia DMU V5-6R2021

- INVENTOR 2021

- SOLIDWORKS 2021

- Forge NXT Cluster

- Mastercam 2021

- PC-DMIS 2020

- Vericut V9.0

- Calypso

- Calypso off-line

Die Shop

Our CNC die sinking centers make up the backbone of our die manufacturing facility. Our die fabrication capabilities are augmented by in-house EDM (Electrical Discharge Machining) for difficult tooling features. APP operates one of the largest in-house forge die shops in the aluminum forging industry in terms of number of dies produced.

Industry Leadership Through Precision Forgings

At Aluminum Precision Products, our expertise spans diverse industries, delivering specialized aluminum forgings that meet the most demanding requirements across sectors. From our roots in aerospace to our expansion into defense, automotive, industrial, and beyond, we maintain our commitment to metallurgical excellence and precision manufacturing. Our unique forging processes create components with superior strength-to-weight ratios, enhanced durability, and optimal performance characteristics. As markets evolve, APP continues to advance aluminum forging technology to meet new challenges, reinforcing our position as the preferred global resource for high-performance, precision-forged aluminum components.